Introduction

Innovations in adhesive materials are rapidly shaping the landscape of modern manufacturing, enabling advancements that were previously unattainable. In high-tech industries, adhesives function as both enablers of technological growth and as gatekeepers for performance standards. Whether in aerospace, automotive, electronics, or renewable energy, the evolving properties of adhesives continually raise the bar for product development and assembly efficiency. The rise of eco-friendly solutions such as bio-based polymers has further propelled the focus on sustainability, inspiring a shift away from conventional adhesives.

Companies are now offering a broader array of high-performance formulations to meet demanding applications. For instance, NXT Level Packaging Hot Melt Adhesive exemplifies the shift toward advanced bonding solutions that prioritize both reliability and operational simplicity. High-tech applications require adhesives that blend precision, flexibility, and durability—all while adhering to strict environmental and safety guidelines.

Advancements in Bio-Based Adhesives

Sustainability is an increasingly critical concern, fueling research into bio-based adhesive materials that utilize waste or renewable feedstocks. Novel approaches have emerged, such as transforming waste cooking oil into high-performance polyester adhesives, a process that maximizes resource efficiency while producing robust, load-bearing materials. This new generation of adhesives demonstrates strength capable of holding substantial weights—some can even tow vehicles—offering both practical utility and reduced environmental impact. Bio-based adhesives help manufacturers reduce reliance on petroleum sources, expediting the transition to greener manufacturing cycles.

Integration of Smart Adhesive Technologies

Beyond mere strength, modern adhesives are becoming “smart,” integrating advanced functionalities to enhance their utility. Self-healing properties, response to environmental stimuli (such as temperature or moisture), and adaptability in changing conditions are central to new product lines. Researchers have harnessed shape memory polymers (SMPs) to create adhesives that “lock” in shape, dramatically improving joint performance under stress or after deformation. These technological leaps are crucial for industries where resilience and reliability are non-negotiable, such as electronics and medical device assembly.

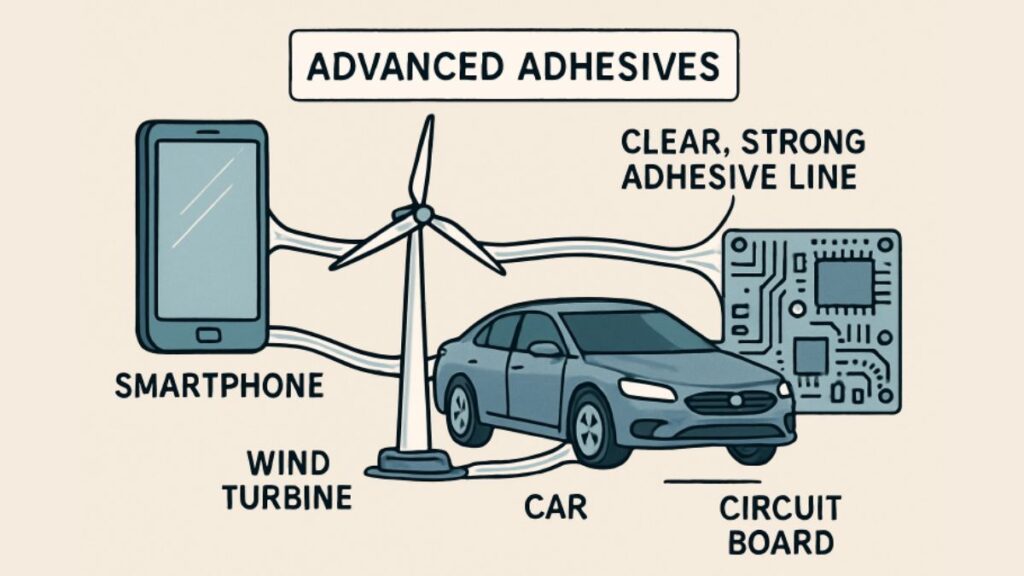

The interplay between flexibility and durability is particularly important for manufacturers that must accommodate rapid assembly changes and stringent product standards. This is evident in chip manufacturing and automotive assembly, where adhesives must adapt not only to physical changes but also to rapidly shifting production demands and technologies.

Role in Lightweight Material Assembly

Lightweight materials are central to the innovation strategies of manufacturers in the automotive, aerospace, and consumer goods sectors. Adhesives enable the seamless joining of metals, plastics, and composites with minimal weight addition—a factor crucial for enhancing energy efficiency, performance, and fuel economy. The global market for industrial adhesives is set to expand rapidly, with a projected CAGR of 4.7% and expected revenues reaching $79.5 billion by 2030. This growth reflects the increasing reliance on adhesives for lightweight, high-strength bonding that complements modern engineering trends.

Enhancing Performance in Electronics

The trend toward miniaturization in electronics poses unique demands on bonding materials. Adhesives in this sector must not only ensure reliable electrical and structural connections but also protect from heat, moisture, and dust. Advanced formulations are now engineered to offer thermal management, resist corrosion, and maintain bond integrity at microscopic scales. This is particularly vital for semiconductors, smartphones, batteries, and wearable technology. As electronic devices continue to shrink and integrate more functions, the performance and adaptability of adhesives remain paramount to device longevity and user safety.

Impact on Renewable Energy Technologies

Renewable sectors such as wind and solar rely extensively on adhesive technologies to assemble turbines, panels, and related systems where screws or welds are impractical. The relentless quest for reliability in challenging outdoor environments has spurred the creation of adhesives with enhanced resistance to UV light, vibration, and thermal shock. By imparting exceptional strength and flexibility, these adhesives help secure operational continuity and support the longevity of renewable installations. This translates to lower maintenance costs, higher system efficiency, and accelerated adoption of green energy solutions worldwide.

Challenges and Future Directions

Despite extraordinary progress, adhesive manufacturers grapple with persistent challenges: aligning high performance with stringent environmental and economic requirements. Next-generation adhesives must not only deliver strength and longevity but also enable recycling and safe decomposition—features vital to a circular manufacturing ecosystem. Research efforts are aimed at developing completely recyclable adhesives, reducing toxicity, and refining lifecycle management. Cross-sector partnerships and academic-industry collaborations will underpin the continued evolution of adhesives that address the unmet needs of tomorrow’s technologies.

Final Thoughts

The future of adhesive materials in high-tech industries is anchored in innovation, adaptability, and sustainability. As developments accelerate, adhesives will continue to be instrumental in driving efficiency, performance, and eco-conscious production across multiple domains. Their evolving role underscores their significance as critical enablers of high-tech progress.